If you own a BMW, you’ve probably heard of the DISA valve. But do you know how it works? This key part helps your engine run better, thanks to a hidden vacuum connection. Understanding this system could help fix engine problems you face.

So, let’s explore the BMW DISA valve and its important vacuum connection.

Key Takeaways

- DISA valves in BMW engines are vacuum-operated components, but their vacuum connection may not always be obvious.

- Some BMW models have DISA valves with an internal vacuum source, with a small round opening at the bottom of the solenoid.

- The vacuum source for DISA valves is used by the Engine Control Module (ECM) to switch the intake manifold configuration for improved low-end torque and high-end power.

- A faulty DISA valve can lead to various engine problems, such as a check engine light, engine rattling, rough idle, and vacuum leaks.

- Proper diagnosis and maintenance of the DISA valve system are crucial to maintaining your BMW’s peak performance.

BMW DISA Valve Components and Function

The BMW DISA (Dynamic Intake System Adjustment) valve is key in the bmw intake system. It controls airflow and bmw air flow regulation. The valve has a flapper and a vacuum-operated solenoid. Both are crucial for engine performance.

Flapper Mechanism Operation

The flapper in the DISA valve manages air intake to the engine’s bmw air mass sensor. It adjusts air flow based on driving conditions. This helps the engine perform better under different situations.

Vacuum Port Locations

The DISA valve’s vacuum port is at the solenoid’s bottom. This spot ensures vacuum pressure moves the flapper smoothly. It connects the valve well with the engine’s intake system.

System Integration Points

The DISA valve is a key part of the bmw intake system. Problems with it can affect engine performance and fuel use. It’s also important for the engine’s long-term health.

Keeping the DISA valve sealed and maintained is vital. Smoke tests show leaks can happen. These leaks can hurt system efficiency and cause engine issues.

| Component | Function |

|---|---|

| Flapper Mechanism | Regulates air intake volume |

| Vacuum Solenoid | Actuates the flapper mechanism |

| Vacuum Port | Provides vacuum pressure for flapper operation |

| Intake Manifold Integration | Integrates the DISA valve with the engine’s air intake system |

Common Vacuum Issues in BMW DISA Systems

BMW’s DISA (Dynamic Intake Swirl Actuator) valve technology was introduced in 1995. It’s used in many BMW models, like the 3-Series and X5. But, these valves don’t last long, lasting only 70,000 to 100,000 miles.

Vacuum leaks are a common problem with BMW DISA systems. These leaks can come from bad connections, missing caps, or faulty seals. They often cause engine codes like 0171 and 0174, related to bmw engine vacuum leaks and bmw throttle body issues.

Smoke tests can find these vacuum leaks. They show problems with the DISA valve and its connection. Fixing these issues helps prevent engine damage and keeps fuel efficiency high.

“The failure of DISA valves can lead to poor fuel efficiency or potentially damage the engine, making it crucial to address any vacuum-related issues promptly.”

The M50 engine family often has DISA valve problems. But, the M52 engine, found in the E39 5-Series, is easier to work on. Replacing the DISA valve is simpler, and bmw throttle body issues are more manageable.

Knowing about common vacuum issues in BMW DISA systems helps owners keep their cars running well. Regular maintenance and timely DISA valve replacements are key. They help keep the engine healthy and avoid expensive repairs later on.

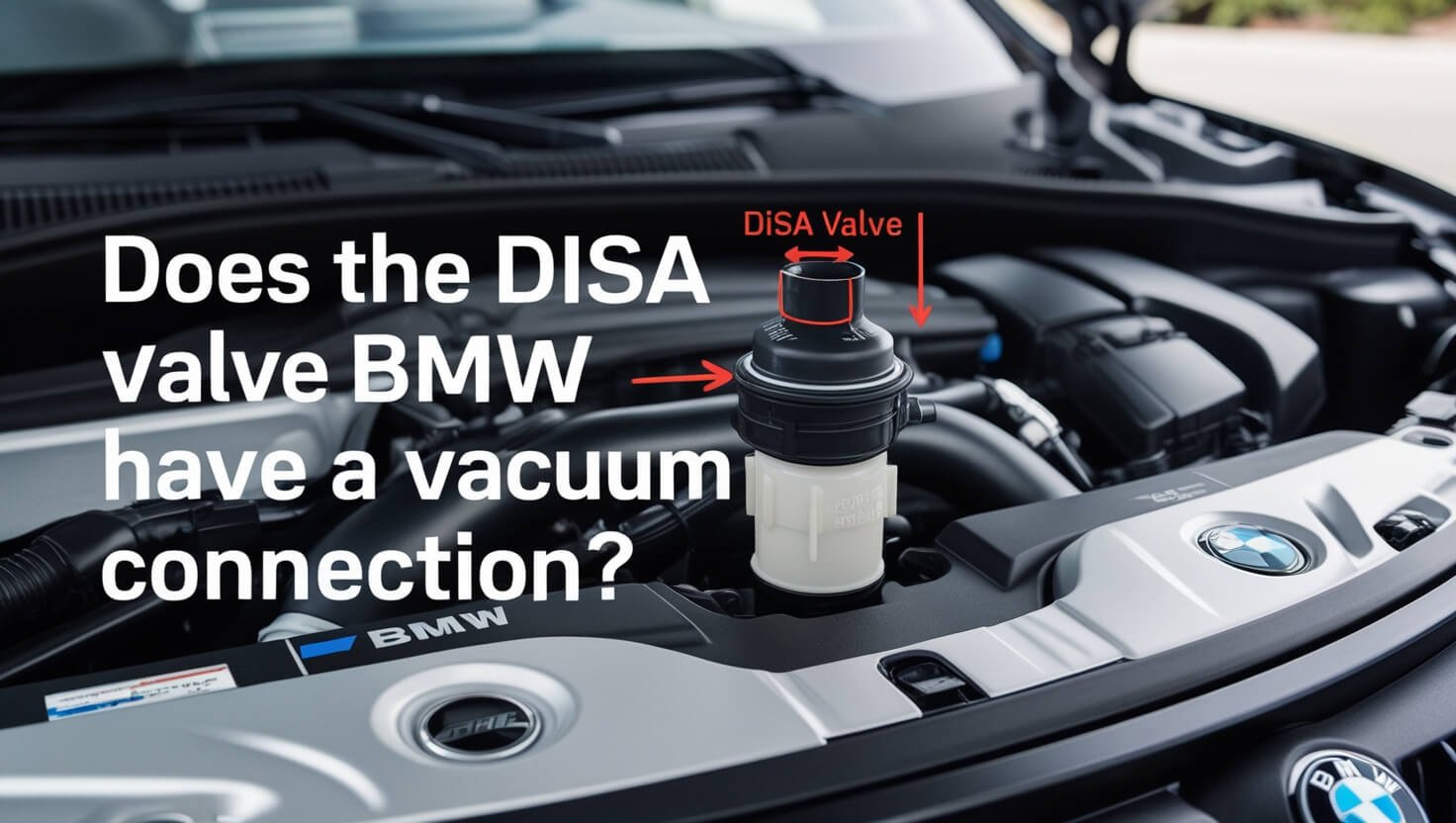

Do Disa Valves On BMW Have Vacuum Connection

Many people think BMW DISA valves don’t have a vacuum connection. But, they actually do, even if it’s not easy to see. Inside the valve, there’s a small vacuum port. This connection is key to how the DISA valve works, helping control air intake for better engine performance.

Vacuum Operation Principles

The DISA valve’s flapper moves thanks to vacuum pressure. When the engine runs, vacuum in the intake manifold makes the valve move. This vacuum connection lets the DISA valve change the intake manifold’s length. This adjustment improves engine performance at different RPMs.

Connecting Points Analysis

The vacuum connection in the DISA valve connects to the engine’s vacuum system. This vacuum reservoir gets pressurized by the manifold. It provides the vacuum force needed to move the valve’s flapper. Knowing about these connections is key for fixing DISA valves right.

Solenoid Functions

The DISA valve also has a solenoid that works with the vacuum system. The solenoid uses vacuum to control the valve’s flapper. This lets the engine management system adjust air flow based on driving conditions. The solenoid’s correct operation is vital for the DISA valve to work well.

To wrap it up, BMW DISA valves indeed have a vacuum connection. It’s a vital part of their design and how they operate. Knowing how this vacuum system works is essential for fixing and maintaining DISA-equipped BMW engines.

BMW DISA Valve Testing Methods

Checking your BMW’s bmw engine diagnostics DISA (Dynamic Intake System Actuation) valve is key. It keeps your engine running smoothly and efficiently. There are several ways to test this important part of the bmw intake system.

Smoke Testing

Smoke testing is a good way to find leaks in the DISA valve body. It works by adding a special smoke to the system. Then, you can see if any smoke leaks out, showing where the problem is.

Flapper Mechanism Inspection

- Technicians use special tools to check the DISA valve’s flapper. They make sure it moves well and seals right.

- This test helps find any problems with the flapper, like sticking or binding. These issues can affect how well the valve works.

Visual Inspection

Looking closely at the DISA valve is also important. You should check for cracks, wear, or damage. This can tell you if the valve needs to be replaced.

DIY Testing

Some BMW fans like to test the DISA valve themselves. They follow tips from car websites and forums. This helps them decide if they need to replace the valve.

Using these testing methods, BMW owners and mechanics can make sure the DISA valve works right. This helps keep your engine running well and efficiently.

Diagnosing DISA-Related Engine Problems

Fixing BMW engine problems linked to the DISA valve needs a detailed plan. First, a smoke test is done to find vacuum system leaks. This test shows if the DISA valve is working right.

Then, checking the DISA system’s pressure is key. The right vacuum levels are needed for the flap to work well and for air flow. Error codes like 0171 and 0174 suggest DISA valve issues, needing more checks.

Smoke Test Procedures

A special tool is used for a smoke test. It adds a safe, smell-free smoke to the intake system. Leaks show up as smoke, helping find the problem. This test helps figure out if the DISA valve is the issue or if it’s something else in the bmw engine diagnostics system.

Pressure Monitoring

Watching the vacuum pressure in the DISA system is important. Low or changing pressure might mean a DISA valve problem. This could mess with bmw air flow regulation. BMW’s INPA software gives live data, helping find the exact problem.

Error Code Analysis

Looking for engine error codes is also key. Codes like 0171 and 0174 point to fuel system problems, often from a bad DISA valve. By looking at these codes and other data, techs can find the main issue and fix it.

Fixing DISA valve problems needs a full check, including smoke tests, pressure checks, and error code scans. This detailed approach helps fix bmw engine diagnostics and bmw air flow regulation issues. Quick action keeps BMWs running well and saves on fuel.

Maintenance and Replacement Procedures

Keeping the BMW DISA valve in good shape is key for your engine’s performance. Regular cleaning and checks on the valve parts help spot problems early. When it’s time to replace the DISA valve, using the right O-ring or RTV sealant is crucial. This ensures a tight seal and prevents vacuum leaks.

While BMW’s own DISA valves are the best choice, Dorman replacements can be a budget-friendly option. Before swapping out the DISA valve, test the old one to see if just replacing the O-ring is needed. Installing and sealing the new valve correctly is vital. It keeps your BMW’s intake system and engine running smoothly.

BMW started using DISA valve technology in 1995, with the E39 5-Series being the first to have it. Since then, many BMW models, like the 3-Series, X3, X5, and Z-Series, have adopted this technology. Although DISA valves aren’t meant to last forever, replacing them is often easy. This is thanks to their easy access and the wide availability of replacement parts.